Background

Background

TCL GUYANA INC (TGI) is a member of the TCL Group. The TCL Group comprises companies located in Trinidad, Barbados, Jamaica, and Guyana. The major activity of the Group is the manufacture and sale of cement and concrete. The Group also manufactures paper sacks and single use slings.

TCL GUYANA INC (TGI) is a cement bagging facility, which was incorporated under the Laws of Guyana in March 2004. The Plant started operations in December 2006. Ideally located at Princess and Water Street, GNIC compound, the Plant sits on 2.580 acres of land leased from the Guyana National Industrial Company Inc.

The primary objectives of the operation are:

- To satisfy Guyana’s current and projected cement needs

- To ensure adequate and timely delivery of conveniently packaged cement for various categories of end users

- To effect a more competitive pricing structure for cement in Guyana and so realize savings for the Guyanese consumer

- To provide increased market coverage and service to Guyana

Company Facilities

The Plant consists of the following major pieces of equipment and structures:

- Four spout bag packer

- Palletizer

- Bulk Cement Load Out System

- Electrical Power Generator

- 3 storage silos each with 2000 tonnes capacity

- Storage Warehouse with 2000 tonnes capacity

- Administrative Building

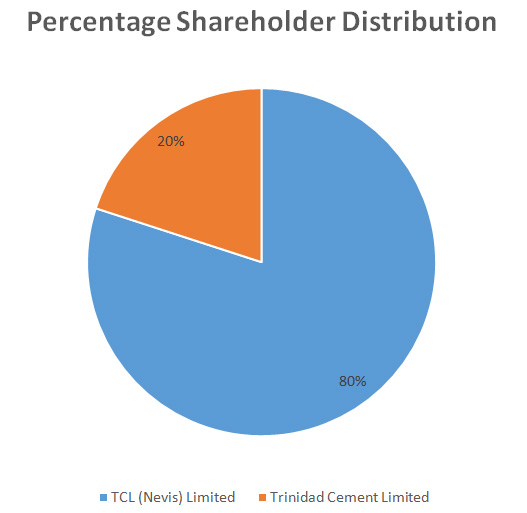

Shareholding and Corporate Governance

The distribution of the shareholding of the company is as follows:

The company has a Board of Directors and a Company Secretary. Arawak Cement Company Limited (ACCL), which has management oversight over TGI, is based in St. Lucy, Barbados. The Business Manager is responsible for the day-to-day operations of TGI, and reports to the Country Manager, ACCL.

Operational Description

Bulk cement is delivered by specialised cement ocean-going vessels and then stored in the silos. The offloading of cement occurs within a closed system with air conveying cement within steel piping to the silos.

Packing of cement bags (42.5 kg bags) is accomplished by an inline four-spout packer system, which is fed by cement extracted from the cement silos through air gravity conveyors and transported via bucket elevator. The filling and packing system is served by a dust plant, which is an integral part of the system, to ensure that cement particles displaced in the air from the filling process are captured and returned to the cement filling process and silos. The capacity of this system is 60 tonnes/hour.

Cement bags (42.5 kg sacks) from the bag packing system are conveyed to the automatic palletizer system where they are automatically stacked onto a pallet. The full pallets are then transported by forklifts to one of three palletizer machines where stretch wrap is applied to the bale of filled cement sacks. The stretch wrapped pallets are then transported by forklift to the warehouse for storage.

Bulk cement trucks (also referred to as bulk road tankers) are loaded by extracting cement from the cement silos with air gravity conveyors. A loading spout is used to fill the trucks. The dust plant will ensure that cement particles entrained in the displaced air from the truck and the air gravity conveyor is extracted from the air stream, and returned to the filling process and silos.

Bulk bag loading i.e filling of the 1.5 tonne bags (also referred to as Jumbo Bags) is done by extracting cement from the cement silos with the same air gravity conveyors that are used to load the bulk cement trucks.

HEALTH, SAFETY AND THE ENVIRONMENT (HSE)

HSE is one of the key pillars of the operations of TGI and the entire TCL Group. All of the cement companies in the TCL Group are ISO 14001:2004 (Environment Management System) Certified.

In terms of Occupational Health and Safety (OHS), TGI is committed to the goal of “Zero Accidents, Zero Incidents”. The company conducts its business under the premise that all incidents, including personal injury, fire, property and equipment damage and production losses are preventable.

TGI is committed to conducting its operations in an environmentally responsible manner. The major objectives of the TGI Environmental Management System are pollution prevention, compliance with legal requirements related to the environmental aspects and impacts of its operations and continual improvement of environmental performance.

All of the cement companies in the TCL Group are ISO I4001:2015 (Environmental Management System) certified.